PHOTO

ABU DHABI: The Ministry of Energy and Infrastructure (MoEI) has announced plans to form a new joint venture with BEEAH, the region’s leading sustainability and innovation pioneer, and LOHUM, India’s largest diversified producer of sustainable critical minerals and advanced materials.

Announced at the World Future Energy Summit on the sidelines of Abu Dhabi Sustainability Week, the partnership will facilitate the development of the UAE’s first, large-scale facility for electric vehicle (EV) battery recycling and second-life repurposing.

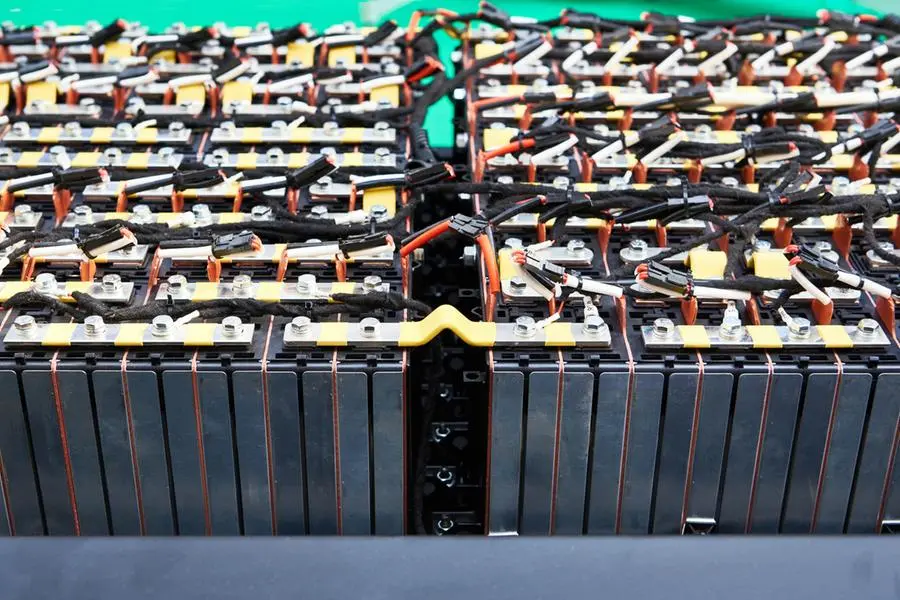

The joint venture builds on an earlier collaboration agreement between BEEAH and LOHUM to bring advanced lithium-ion battery recycling to the UAE. To be located within BEEAH’s integrated Waste Management Complex in Al Saja’a, Sharjah, the facility will have the technology to recycle and repurpose EV batteries, as well as other types of Lithium-ion batteries, enabling the UAE’s broader circular economy strategy.

In 2026, it aims to process 1,500 tonnes of Lithium-ion batteries and, by the third year of operations, double its processing capacity.

Through integrations with its software platform, the joint venture will also offer producers end-to-end traceability and visibility, from the collection and tagging of end-of-life Lithium-ion batteries to recycling and repurposing. This will empower producers to remain compliant with regulations, benefit from buyback programs, and actively participate in the circular economy.

Sharif Al Olama, Under-Secretary for Energy and Petroleum Affairs at the Ministry of Energy and Infrastructure, said, “This partnership is aligned with the national agenda to manage electric vehicle batteries through localised innovations. This will be achieved through the establishment of a specialised facility that operates at the highest technical and environmental standards, strengthening circularity and the UAE’s readiness to keep pace with the rapid growth of electric mobility.”

He added that the project represents a key pillar in the national roadmap, which positions the UAE as a global hub for electric vehicles and targets 50 percent of vehicles to be electric by 2050.

He noted that the initiative supports the reduction of emissions in the transport sector, while contributing to the development of local industrial capabilities and creating sustainable economic opportunities.

He also said the project addresses end-of-life battery challenges through an integrated, national framework that enhances long-term sustainability and competitiveness, strengthens supply chain resilience for critical battery materials, and reinforces the UAE’s position as a regional hub for clean energy technologies.

Khaled Al Huraimel, Group CEO and Vice Chairman, BEEAH, said, “For BEEAH, this project is a natural extension of our broader circularity strategy, demonstrating how sustainability unlocks value across future-critical industries. By joining forces with MoEI and LOHUM, we are proactively addressing end-of-life EV battery lifecycle management and reducing reliance on landfills, as demand for electric mobility surges. The facility’s strategic location within our flagship waste management complex further reinforces BEEAH’s commitment to managing emerging waste streams and achieving Sharjah’s zero-waste target.”

Sachin Maheshwari, Chief Corporate Development Officer, said, “We look forward to expanding our collaboration with BEEAH and welcome MoEI as a partner in this national initiative. As a leading global producer of sustainable critical minerals and advanced materials, LOHUM’s integrated battery recycling and repurposing solutions are designed to maximise the remaining useful life of lithium-ion batteries before extracting critical materials with zero-waste efficiency. This approach not only cuts carbon footprint but also ensures that raw materials are reintroduced into the supply chain. Together, we aim to build a world-class facility that supports the UAE’s sustainability vision and accelerates the global shift toward clean energy.”

The plant will introduce a full-circle recycling approach, beginning with the repurposing of used EV batteries for second-life applications such as energy storage systems, followed by the safe dismantling of components for extraction. Using LOHUM’s patented NEETM® technology, the facility will then recover valuable materials including lithium, cobalt, nickel, and graphite for reintegration into the circular economy instead of being landfilled or re-sourced from international supply chains. Research indicates that prioritising reuse before recycling significantly lowers the carbon and resource footprint associated with virgin battery production and disposal.