PHOTO

UK-based compressed energy technology company Storelectric is in talks with investors and developers in the Middle East for large scale underground hydrogen storage solutions, a top executive told Zawya Projects in an exclusive interview.

Mark Howitt, Chief Technical Officer and Founding Director, Storelectric said: “So far we have raised 2-million-pound-sterling from a number of small investors. Now we're looking for large investments of £25 million-£75 million ($38 million-$92 million) or even more and we have received investor interest from the Middle East as well.”

Howitt is also a United Nations Economic Commission for Europe expert in energy transition technologies, a Member of the UK advisory team to the International Energy Agency and Member of the Energy Storage Steering Group of the Renewable Energy Association.

He said the firm is talking to a number of promising partners and customers throughout Europe, Middle East and North America.

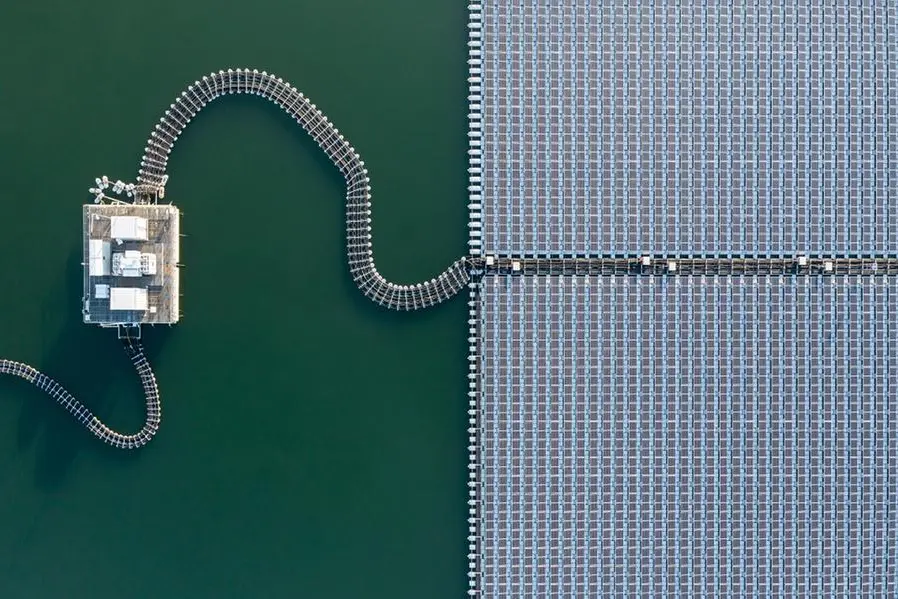

“There is also potential in North Africa especially in relation to solar energy exports through interconnectors,” he said.

Competitive CAES

Storelectric has invented and developed solutions that have made Compressed Air Energy Storage (CAES) competitive in terms of efficiency, costs and emissions and hydrogen compatible, he explained.

“Given the right regulatory environment, the plant would be profitable from day one,” he said, adding that the company’s CAES solutions can offer 30-60 percent return on investment (ROI) standalone and 50-70 percent ROI when combined with renewables, lowering capital costs and improving the profitability of renewables.

“We have already got letters of intent to construct the plants at very good value. We're talking with three businesses with a view to starting one. The funds would be used to making the plants shovel-ready,” he said.

Howitt said salt caverns are good for cost effective storage of large- scale hydrogen at high pressures, and for longer durations, provided they are properly equipped.

“The potential in the MENA is enormous as there are salt basins in every country in the region,” he said.

He pointed out that capital costs would depend on the storage technology and the operating expenses would be akin to a similar sized gas-fired power station but noted that below 20 megawatts (MW) it “becomes exponentially less efficient and more expensive per unit of output and so the plant can't be built small.”

“The smallest Hydrogen CAES that can be built is 75MW, 325 megawatt hours (MWh), for about £80 million assuming that we are able to repurpose existing caverns. The smallest Green CAES, the adiabatic one (which does not burn fossil fuel for process heating) is 40 MW, 200 MWh, and would cost about £50 million under the same principles. The smallest hybrid version would be 106 MW at the cost of about £90 million.”

He said he expects the costs for Hydrogen CAES to fall by 10 percent and Green CAES technology by 30 percent over the first five plants or so.

“Our storage would be cheaper than an equivalent battery because the prices are grid-to-grid and include the costs of grid connection, land, property, buildings, and all sundry activities. It's also more proficient than batteries on a grid-to-grid basis and has five times the life of a battery.”

Elaborating further, he said: “The plant is built using off-the-shelf equipment and could be procured globally on a competitive basis. Costs like land, manpower, construction work, and balance of plants are likely to be done using in-country resources and these could account for 30 percent to up to 80 percent of the plant costs.”

Better than traditional

Howitt said traditional compressor energy storage is not far off 50 percent efficient grid-to-grid but Storelectric’s version is in excess of 60 percent efficient.

When compression heat is stored separately and reused for expansion, he said it raises the roundtrip efficiency grid to grid to about 70 percent and eliminates all emissions from day one.

“When connected to a gas grid, it can take any amount of hydrogen from zero to 100 percent and the storage plants will decarbonise as the gas grid decarbonises.”

He said it would take 3-4 years to construct a small plant with an existing cavern and 5-7 years for a large plant if new caverns have to be made.

Storelectric has filed a patent for High Temperature Hydrogen technology, which the company expects to be cost competitive with other sources of electrolysis.

“We estimate that it would take up to three to four years to be commercialised,” he said.

Grid reinforcement costs

Howitt said incorporating large-scale renewables with large-scale, long duration, inertial storage can vastly save grid reinforcement costs.

“Grid forecasts imply costs well over a billion pounds per Gigawatt hour beyond 16 percent renewable penetration. The American grid needs to triple and in the Middle East, it would be more like four to six times. You need to vastly increase the scale of the grid unless you take the large-scale renewables through similarly large-scale, long duration and inertial storage. Then you can avoid somewhere between half and 2/3rds of the reinforcement costs, and it makes energy transition more affordable and the entire electricity system more reliable, resilient, cheaper, and easier to control, saving both capital and operational costs.”

“The Middle East is fortunately at an early stage of decarbonising and therefore they are able to prevent this happening by doing it the right way.”

Electrolyser costs

Howitt said storage can reduce the capital and operational costs of electrolysis, which needs near baseload electricity to operate efficiently.

“How much cheaper can electrolysis get has not been evaluated yet, but you can reduce the number of electrolysers by a factor of 6 and 10 by using our storage because it needs a lot fewer electrolysers and they are being used efficiently.”

Howitt said technical risks have been evaluated by big multinational engineering firms such as Costain, EON, Siemens, Mitsubishi.

“Siemens and Mitsubishi have both said that they can build the whole top-side plants from catalogue and Mitsubishi has even offered to discuss EPC (Engineering Procurement Construction) guarantees for the first-of-the-kind plant. EPC performance guarantees are virtually unheard of for a first plant, so that tells a lot about their technical risk assessments,” he concluded.

(Reporting by Sowmya Sundar; Editing by Anoop Menon)