PHOTO

United Arab Emirates: Emirates Global Aluminium, the largest industrial company in the United Arab Emirates outside oil and gas, today announced a milestone in its development of a bauxite mine in the Republic of Guinea, West Africa, as the biggest single piece of equipment for the project arrived in the country.

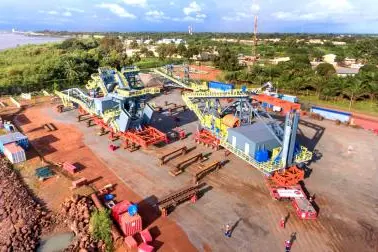

EGA’s subsidiary Guinea Alumina Corporation is developing a bauxite mine and associated export facilities in Boké province in the largest greenfield investment in Guinea in the last four decades. Bauxite is the ore from which aluminium is derived.

GAC’s stacker reclaimer weighs 1,300 tonnes and will now be installed at the company’s site in Kamsar.

When GAC’s mine is operational, the stacker reclaimer will be used to stack bauxite ore arriving at Kamsar by rail. It will also reclaim and place ore on a conveyor system for transport along GAC’s pier to waiting barges.

EGA is expanding upstream and internationally to secure the natural resources the UAE’s aluminium industry needs, and to create new revenue streams for the company. In addition to the GAC project, EGA is building the UAE’s first alumina refinery in Abu Dhabi. EGA’s Al Taweelah alumina refinery will process bauxite into alumina, the feedstock for aluminium smelters.

Abdulla Kalban, EGA’s Managing Director and Chief Executive Officer, said: “The arrival of this huge piece of equipment in Guinea is another big step forward in the GAC project, bringing us ever closer to producing and exporting our first bauxite ore. The stacker reclaimer will become a landmark in Kamsar, as it works over the decades ahead as a crucial part of our production system transforming bauxite into value for Guinea and for EGA.”

GAC has already completed the infrastructure on which the stacker reclaimer will be installed. This consists of a concrete structure that incorporates special rails, which the stacker reclaimer will move along as it stacks and reclaims ore.

The bauxite that is stacked and recovered by the stacker reclaimer will be unloaded from GAC’s rail wagons using another large piece of equipment, the car dumper. This equipment arrived in Guinea in June.

First bauxite exports from the GAC project are expected during the second half of 2019.

The stacker reclaimer was delivered to Kamsar port from China in 12 separate modules. Each part will now be carefully moved to GAC’s site by rail, in a process that is expected to take several days.

Once assembled the stacker reclaimer, which resembles a large crane, will be some 125 long and 25 meters high.

More than 3,000 people, over 80 per cent Guineans, are currently building GAC’s project. The project has a total budgeted project cost of some $1.4 billion.

Once full ramp up is achieved, the project is expected to produce some 12 million tonnes of bauxite per year.

-Ends-

About EGA

Emirates Global Aluminium is equally-owned by Mubadala Investment Company of Abu Dhabi and the Investment Corporation of Dubai.

It is the largest industrial company in the United Arab Emirates outside the oil and gas industry, and the largest company jointly owned by the two Emirates.

EGA’s aluminium is the second largest made-in-the UAE export after oil and gas. In 2017, EGA produced 2.6 million tonnes of cast metal. EGA is the only UAE producer and makes the UAE the fifth largest aluminium producing nation in the world.

EGA has more than 350 customers in over 60 countries. About 80 per cent of EGA’s production is value added products, one of the highest proportions of any aluminium company in the world.

EGA’s aluminium is primarily used in the construction, automotive, packaging, aerospace and electronics industries.

Over 10 per cent of EGA’s production is sold in the UAE to around 26 downstream aluminium companies that make products with EGA’s aluminium. The growing broader aluminium sector in the UAE already employs around 30,000 people, making it the largest employer amongst the UAE’s energy intensive industries.

EGA itself employs around 7,000 of these people including almost 1,200 UAE Nationals.

EGA has focused on technology development for over 25 years. EGA has used its own technology for every smelter expansion since the 1990s and has retrofitted all its older production lines. In 2016 EGA became the first UAE industrial company to licence its core industrial process technology internationally.

As a corporate citizen of the UAE, Emirates Global Aluminium aspires in all its operations to be measured amongst the world’s leading metals and mining companies in meeting its environmental and social responsibilities.

In 2017, EGA became the first Middle East headquartered company to join the Aluminium Stewardship Initiative, a global programme to foster greater sustainability and transparency in the aluminium industry.

EGA was formed in 2014 through the merger of Dubai Aluminium and Emirates Aluminium.

DUBAL’s Jebel Ali aluminium smelter began production in 1979. At almost five square kilometres, EGA’s Jebel Ali site is five times bigger than Dubai Mall.

EMAL started production in 2009 and its Al Taweelah aluminium smelter was the largest single-site aluminium smelter in the world when completed. EGA’s Al Taweelah site is five times bigger than Al Maryah Island at six square kilometres.

EGA has its own power stations at both sites, producing electricity to meet its needs. EGA’s electricity generation capacity is 5,450 megawatts, making EGA the third largest electricity generator in the UAE after the Dubai Electricity and Water Authority and the Abu Dhabi Water and Electricity Authority.

EGA also produces water through desalination units at its power plants. In addition to meeting its own water requirements, EGA supplies 1.5 per cent of the water needs of Dubai as well as commercial water customers and bottlers.

Today EGA is expanding upstream and internationally to secure the natural resources the UAE’s aluminium industry needs and create new revenue streams.

EGA’s wholly-owned subsidiary Guinea Alumina Corporation is building a bauxite mine and associated export infrastructure in the Republic of Guinea in West Africa, in one of the largest greenfield investments in that country in over 40 years.

In the UAE, EGA is building the country’s first alumina refinery at Al Taweelah. The project will reduce the UAE’s dependence on imported alumina and supply 75 per cent of the Al Taweelah smelter’s needs.

For more information on EGA please visit www.ega.ae.

Contacts at EGA:

Simon Buerk

sbuerk@ega.ae

056 3111 536

Fatima Al Mutawa

falmutawa@ega.ae

050 327 7545

Khadija Al Marzooqi

kalmarzooqi@ega.ae

050 8777 850

Sahar Farhat

sfarhat@ega.ae

050 1213 420

Ameera Al Marzooqi

amarzooqi@ega.ae

050 957 9672

Disclaimer: The contents of this press release was provided from an external third party provider. This website is not responsible for, and does not control, such external content. This content is provided on an “as is” and “as available” basis and has not been edited in any way. Neither this website nor our affiliates guarantee the accuracy of or endorse the views or opinions expressed in this press release.

The press release is provided for informational purposes only. The content does not provide tax, legal or investment advice or opinion regarding the suitability, value or profitability of any particular security, portfolio or investment strategy. Neither this website nor our affiliates shall be liable for any errors or inaccuracies in the content, or for any actions taken by you in reliance thereon. You expressly agree that your use of the information within this article is at your sole risk.

To the fullest extent permitted by applicable law, this website, its parent company, its subsidiaries, its affiliates and the respective shareholders, directors, officers, employees, agents, advertisers, content providers and licensors will not be liable (jointly or severally) to you for any direct, indirect, consequential, special, incidental, punitive or exemplary damages, including without limitation, lost profits, lost savings and lost revenues, whether in negligence, tort, contract or any other theory of liability, even if the parties have been advised of the possibility or could have foreseen any such damages.