PHOTO

Doha, Qatar: The largest 3D construction printer in the world has been installed at a school construction site in Doha.

The first of the two BODXL printers, measuring 50m x 30m x 15m (the size of a Boeing 737 hangar), manufactured by COBOD International and operated by UCC Holding, was revealed during a special VIP event recently.

The successful installation of the printer, which is over four times larger than the next largest 3D construction printer ever developed, occurs less than 10 months after UCC Holding and Denmark’s COBOD, the foremost manufacturer of concrete 3D printers globally, signed a contract on September 18, 2024 to provide the world’s largest third-generation 3D printers intended for school construction in Qatar.

As stated in a LinkedIn post by UCC Holding, the printer will be utilised in the construction of two public schools in Doha, each covering 20,000 sqm, resulting in a total of 40,000 sqm, thus establishing this as the largest 3D printed construction project in the world to date.

With its vast scale, the BODXL can print a building footprint of 1,500 square metres and structures reaching up to five floors, culminating in a total built-up area of 7,500 square meters.

According to VoxelMatters — an independent resource for additive manufacturing industry news — the installation of the printer is merely the beginning as a second BODXL printer, identical in dimensions, is already on its way to Qatar and is scheduled to be installed later this month at the same site.

Once both machines are fully operational, they will work together to create the largest 3D printed building in the world—a multi-thousand square metre school for Qatar’s Public Works Authority, Ashghal, VoxelMatters reported.

The simultaneous deployment of these cutting-edge printers is a pivotal element of what is poised to become the largest 3D construction automation initiative in the world.

The educational facility, spanning approximately 40,000 square metres across two locations, is set not only to establish new records but also to transform expectations regarding speed, sustainability, and accuracy in architectural design and implementation.

This endeavour is anticipated to achieve recognition from Guinness World Records as the largest edifice constructed using 3D printing technology.

Beyond its ambitious dimensions, the project is in harmony with Qatar’s long-term sustainability objectives as outlined in the Qatar National Vision 2030, as it significantly minimises material waste and curtails the carbon footprint in comparison to conventional construction practices.

Employing COBOD’s third-generation BODXL machines introduces a high degree of automation and digital accuracy to the construction process.

This system guarantees expedited project completion and enhanced resource efficiency by diminishing the reliance on manual labour and traditional materials.

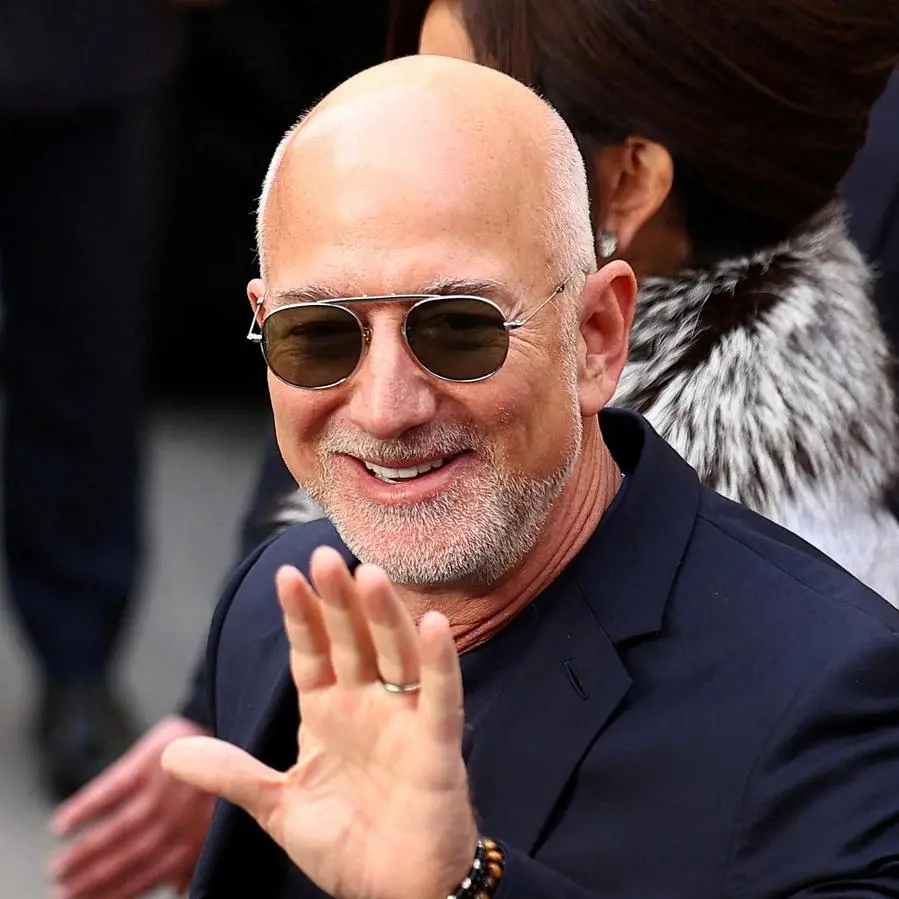

VoxelMatters reported that Henrik Lund-Nielsen, the CEO and founder of COBOD International, emphasised that the collaboration with UCC Holding signifies a major technological and environmental progress. He praised the scale of the project and its ability to initiate a new phase of intelligent, sustainable construction efforts worldwide.

Leaders at UCC Holding also expressed their pride in promoting this ambitious and forward-thinking project, placing Qatar at the forefront of global innovation in civil engineering.

Construction operations utilising the printer are anticipated to increase significantly during 2025, resulting in the realisation of a forward-thinking educational institution through advanced engineering techniques.

This initiative for the Doha school is not merely a construction achievement; it is projected to be the inaugural project in a succession of large-scale buildings that can be developed swiftly, cost-effectively, and with reduced environmental consequences via 3D printing.

The printers are expected to operate at the fastest printing speed possible, ensuring rapid completion while maintaining high standards of safety and sustainability.

© Dar Al Sharq Press, Printing and Distribution. All Rights Reserved. Provided by SyndiGate Media Inc. (Syndigate.info).