Jim Dymock, Cosmoplast General manager was recently interviewed by Pipeline magazine's Jyostna Ravishnkar about how operations at the new RTP factory in Abu Dhabi was devoloping.

1) The RTP plant has been opened recently in Abu Dhabi. The plant is the first of its kind being dedicated to producing RTP? How have the first few months been in terms of production?

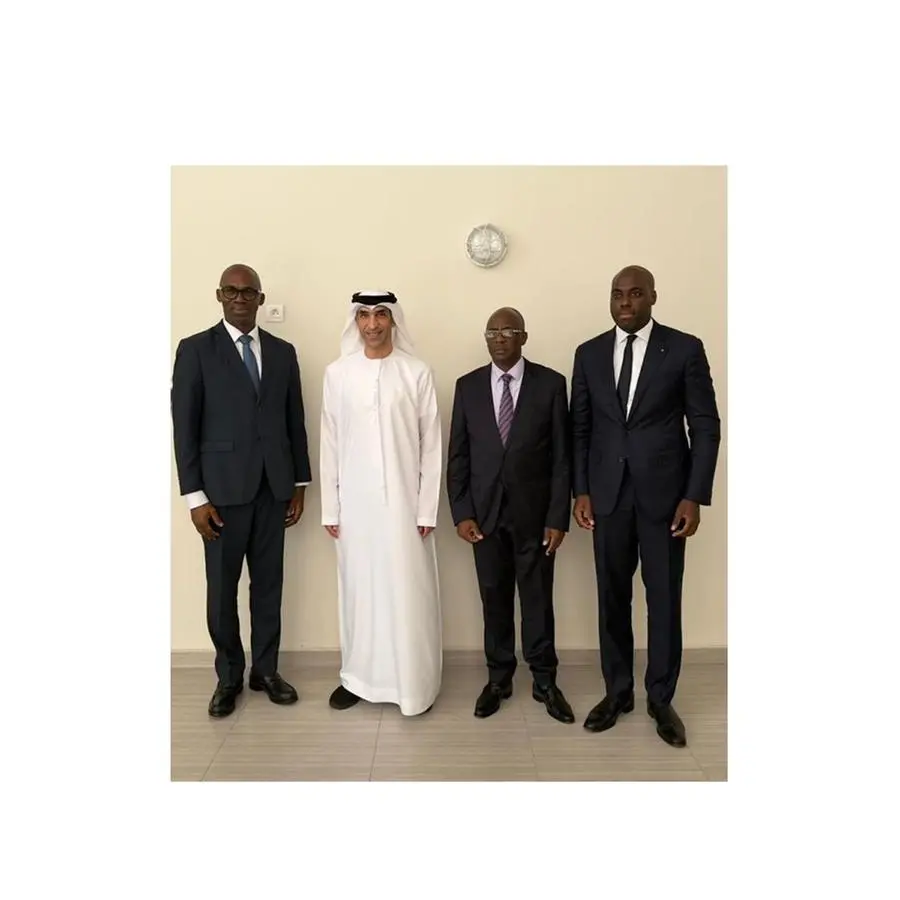

Cosmoplast's production plant in Abu Dhabi was officially opened by Mr. Mohammad Ali Bin Zayed, Deputy Governor of the U.A.E. Central Bank on April 21st of this year, since then the factory has been undergoing final operational shakedown and the establishment of optimum production and logistical parameters. The plant is the first of its kind outside Europe to produce Coflexlite Reinforced Thermoplastic pipes (RTP), and represents the recognition of progressive manufacturers like ourselves and our JV partners Technip that it is essential for the industry to produce the product locally to meet the needs and requirements of our regional customers. In this particular aspect, September will see the first shipments of RTP product out to our customers.

2) How has the response from the oil and gas sector been for these pipes? What is the exact benefit of using the pipe as against the traditional steel pipes?

The response from the regional oil and gas sector has been extremely strong. The recognition of the benefits and advantages of the Coflexlite RTP system have already been well established in the market. Now having the product produced locally enhances its attraction even further. The primary advantages against steel pipes are; no corrosion, either from the internal or external pipe environment; jointing parameters reduced from major welding and weld testing requirements to a much simpler and easier bolted flange joint configuration; pipe jointing intervals at up to 600 metres (depending upon client requirements) instead of every 10-12 metres; major reduction in installation times, costs and crew requirements; minimal ongoing maintenance requirements; no need for anti corrosion support structures used to keep steel pipes suspended in the air and away from potentially corrosive contact with the ground. Depending upon types of installation equipment used and terrain encountered, actual speed of RTP pipe installation or retrieval is expected to run at about one to two kilometres per hour. In addition to this, once a particular Coflexlite RTP oil or gas line is no longer required then it can be easily unhooked, picked up, relocated and used elsewhere. In recent comparative pipe tests run by British Gas, they have shown that Coflexlite RTP is highly suitable for pure gas transportation, unlike other design types of RTP which they have similarly tested.

3) The benefits listed for RTP is that it is cost effective while being long lasting. Can you tell us of the technology which makes you achieve both?

Coflexlite pipe utilises a wholly non-metallic construction making it entirely resistant to virtually all corrosive agents typically found in an oil or gas production environment. Specifically these include water, H2S, CO2, aromatics, acids and bases and as such these will not in any way affect the mechanical integrity of the pipe over its design life. In addition, the product's polymeric construction lends itself to provide the additional benefit of resistance to erosion. The damage tolerance of the liner material means that any particulate or multi-phase flow will not compromise the pipe structure in anyway. These properties serve the end user to dramatically reduce operational expenditure and costs associated with pipeline inspection and maintenance and therefore provide huge cost saving benefits over the operational life of the pipeline. The product is light-weight and flexible, and can be supplied on road transportable coils in lengths of up to 600m. This inherent property means that all logistics associated with installation and jointing are significantly simplified and, as a result, pipes can be very rapidly installed with minimum expense. Potentially, this can provide massive capital expenditure cost savings for end users of the product. In addition to this, it is possible to lay Coflexlite directly onto the ground without the need for regular support systems, expansion loops or specialised bends; this again can generate further substantial savings on total project costs and lifespan maintenance.

4) Can you tell us of some of the clients who use this RTP pipes is the GCC? Have you any clients outside the GCC using these pipelines at present or intending to use it in the near future?

Previously, different types of RTP have been used in Oman, Saudi, Egypt and Kuwait, however the design structure of the RTP used was of a bonded nature and not the unbonded configuration which is one of Coflexlite's inherent advantages. The bonded structure and design of these RTP products, which were imported from Europe, makes then unsuitable for use with pure gas environments. External to the G.C.C., Shell / Mobil have installed Coflexlite RTP in a pipe-in-pipe use to refurbish old steel pipes and to allow the flow of wet H2S gas which ordinary steel pipes cannot do, another recent installation has been a special test line for ADCO in Abu Dhabi and presently strong interest is being received from both Aramco and Qatar Petroleum. In fact one of our first commercial production runs from the Abu Dhabi plant was produced for a BP / Bechtel installation in Georgia.

5) The pipelines are supposed to be resistant to most corrosive materials found in the oil and gas industry. What testing methods do you use before supplying the RTP to your clientele?

As noted earlier, the pipe being made of a High Density Polyethylene (HDPE) thermoplastic material means that it is entirely resistant to virtually all corrosive agents found in oil and gas distribution networks. In relation to testing, HDPE materials and pipe testing procedures are applied at various stages during the production process, however to complete the whole process, all pipes are then fully pressure tested prior to shipment. During these procedures all pipes are fully tested in accordance with the industry standard for RTP and all completed pipes will come with their own fully verified test certificates.

6) Apart from the oil and gas sector, which are the other sectors that can use RTP? Are the RTP's manufactured according to specific requirements?

Interest has been shown in other fluid transportation sectors, these are primarily related to where operational pressures or temperatures are running above normal thermoplastic pipe parameters, or where a supply line is urgently needed thus allowing RTP to come into its own with its long lengths and minimum connection and installation timeframes. One example of this was in the Bahamas where an inter-island water supply line was urgently needed, as required this was quickly shipped, installed and commissioned. The design of Coflexlite RTP is specifically targeted at parameters within the oil and gas industry, thus yes it is made to specific industry requirements, however on an order by order basis, parameters are customized on a unit length and connector / joint specification to suit customer needs. If so required by the customer, pipes could also be supplied in a semi-finished condition, that is without end fittings installed, once on site and exact connection locations established then the end fittings would take about half an hour to install by specialized hand transportable equipment.

7) As a manufacturer, how would you classify the RTP manufactured in your plant as different from other plants in terms of pipe production?

8) What is the kind of fibre which is used in the RTP supplied to the oil and gas industry?

Coflexlite RTP is unique in that it has a reinforcing structure which comprises of a specialized design of woven aramid fibre. These aramid fibres are the same type of material which is used to make bullet proof vests, thus indicating the strength and toughness of the material used. In utilizing this unique and specialized tape design as a reinforcement medium, it has allowed the Technip design team to take the pipe up to an optimum pressure capability which cannot be matched by any similar type of RTP structure.

9) Is Cosmoplast coming out with any more new products for this year? If yes are they in partnership with other manufacturing companies?

For Cosmoplast the rest of the year will be more a consolidation and capitalization of some of the projects which Cosmoplast has been working on and has introduced over the last twelve to eighteen months. These have included 1,200mm diameter 10 Bar HDPE water distribution pipes, a major contract of which has just been completed and shipped to the client. Other products include preinsulated pipe for district cooling systems utilizing HDPE core pipes encapsulated in polyurethane insulation and then protected by HDPE outer jackets, PEX pipe systems used in both gas and water distribution systems, Random Copolymer Polypropylene pipes for use in hot and cold water distribution systems, and we have recently had a significant development in our pioneering use of UPVC manholes of up to 1,500mm in diameter. With these units we have recently finalized orders for part of the major new sewerage distribution scheme now under construction by the Ras Al Khaimah Sewerage Authority. In irrigation systems we are in collaboration with a South African company on the use of a new and highly efficient water sprinkler system which ensures that a uniform size of water droplet is formed, thus resulting in virtually no water losses due to small droplets being wastefully blown away from the required area of irrigation, I'm sure that all of us at one time or another have seen the clouds of fine water mist being blown away and lost in the wind from irrigated areas, this mist and associated small droplet evaporation can comprise of over 33% loss of the total water input into an irrigation system. Although many of these products relate to other forms of pipe usage rather than that of a hydrocarbon nature, this diversity of product shows the strength and depth of expertise that Cosmoplast can bring to match and meet the solutions required by pipe end-users. In addition to this Cosmoplast is now close to starting the building phase for our new pipe factory in the Dubai Investment Park, this has been designed to product both UPVC and HDPE pipes up to 630mm in diameter, while also is the designated plant for the manufacture of our preinsulated pipes for use in district cooling systems. In parallel to the Dubai plant we already have another 60,000 square metres of land and the plans in progress for the construction of our second pipe plant for UPVC and HDPE products in the Abu Dhabi area.

-Ends-

© Press Release 2005