PHOTO

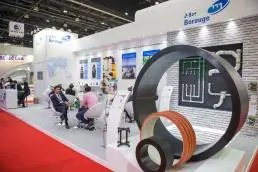

Borouge, a leading petrochemical company that provides innovative, value creating plastics solutions, showcased its portfolio of sustainable and value-added plastics solutions for the civil infrastructure applications and construction industry at the Big 5, an international building and construction tradeshow, held in Dubai from 23-26 November 2015.

The Big 5 fair provided Borouge with an opportunity to demonstrate its wide range of polyolefin products for water, gas and heating piping systems for domestic and industrial buildings and constructions, in addition to wire and cable solutions.

"Big 5 is a key event for Borouge to meet with our partners in the water and energy industry value chain. An ideal platform to share thoughts and ideas on the latest trends moving the industry forward as well as to learn about successes achieved and best practises from the leaders in the industry," said Hazeem Sultan Al Suwaidi, Senior Vice President Middle East Africa (MEAE), Borouge.

At Big 5, Borouge offered a range of high quality PP-R, PP-RCT and PEX polypropylene and polyethylene materials for the manufacture of hot and cold water and gas pipe systems. These corrosion resistant materials, which are rapidly replacing metal pipes in buildings throughout Europe, Asia and the Middle East, provide long maintenance free operation at high temperatures.

"Such a demanding application requires materials to be produced up to the highest standards because any failure of a system in a large building or complex can result in high costs," said Robin Bresser, Vice-President of Marketing Centre Pipe, Borouge. "In addition, as the pipes are transporting drinking water, it is also essential that they should be safe and contamination free to ensure protection of the public health."

As testament to its core properties of strength and flexibility, BorSafe™ HE3490-LS from Borouge has been officially qualified by the US Nuclear Regulatory Commission as a material meeting the requirements of the American Society of Mechanical Engineers (ASME) Code Case N-755-1 for Class 3 Safety-Related Applications, making it the first PE100 material in the world to be certified for use in nuclear applications.

"With the increasing global demand for alternative energy, the approval for our BorSafe™ HE3490-LS will open up exciting new opportunities for us and PE100 piping in the nuclear power industry, especially in view of projects announced in the Middle East and China," Robin Bresser added.

In line with its commitment to 'bringing energy all around', Borouge also demonstrated at the Big 5 tradeshow Visico™ Ambicat™ cross-linked polyethylene (XLPE) grades for insulation of cost effective low voltage power cables. Borouge also showcased a selection of Borlink™ and Borstar® solutions ensuring the reliability of medium voltage distribution cable systems.

For further information, please contact:

Rehab Omar Ateeq, Regional Communications Manager MEAE, Borouge

Tel. +971 2 6070805, Rehab.Ateeq@borouge.com

About Borouge

Borouge is a leading petrochemical company in providing innovative, value creating plastics solutions. A joint venture between the Abu Dhabi National Oil Company (ADNOC), one of the world's major oil and gas companies, and Austria based Borealis, a leading provider of chemical and innovative plastics solutions, Borouge is a groundbreaking joint venture at the forefront of the next generation of plastics innovation.

With its base in the United Arab Emirates and Marketing & Sales head office in Singapore, Borouge employs more than 3,000 people representing over 40 nationalities and serves customers in 50 countries across the Middle East, Asia and Africa.

Building on the unique Borstar® and Borlink™ technologies and over 50 years of experience in polyolefins, Borouge provides innovative, sustainable and value creating plastics solutions for infrastructure (pipe systems, and power and communication cables), automotive and advanced packaging applications that address global challenges such as climate change, food protection, access to fresh water, energy conservation, healthcare and waste management.

In 2010 Borouge tripled the annual production capacity of its plant in Abu Dhabi to 2 million tonnes, and with further expansion to 4.5 million tonnes in 2014, Borouge and Borealis will have a combined annual production capacity of approximately 8 million tonnes of polyethylene and polypropylene.

Borouge is expanding its commercial and logistics network in the Middle East and Asia and investing in its Innovation Centre in Abu Dhabi and R&D Application Centre in Shanghai. Focused on our company mission, Value Creation through Innovation, we ensure that our customers throughout the value chain, around the world, can rely on differentiated products and reliability of supply.

Borouge is committed to the principles of sustainability and is a signatory of the chemical industry's Responsible Care® Global Charter. Together with Borealis, Borouge is proactively addressing the world's water and sanitation challenges through the Water for the World™ initiative.

Visit www.borouge.com and see how we are Shaping the Future with Plastics.

Learn more about

Borouge at www.borouge.com

Borealis at www.borealisgroup.com

Water for the World at www.waterfortheworld.net

© Press Release 2015