PHOTO

Fast Facts

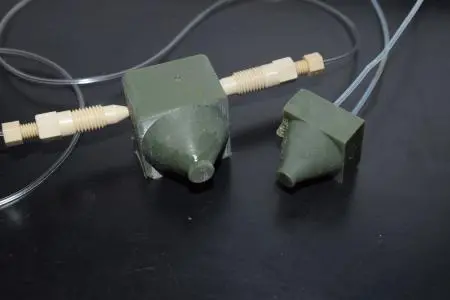

● NYU Abu Dhabi researchers used a 3D printer to replicate a sophisticated, microfluidic probe (MFP) used in biosciences and cancer research.

● The 3D printed device is less expensive than the original made of glass and silicon, and works just as effectively.

● Findings suggest that 3D printers could improve access to technologies essential for scientific discovery and pave the way for engineers to develop integrated and more advanced devices.

● The study results were recently published in the journal Scientific Reports - Nature.

Abu Dhabi: NYU Abu Dhabi Assistant Professor of Mechanical and Biomedical Engineering Mohammad Qasaimeh, and NYU Abu Dhabi Global PhD Fellow in Engineering and first author of the research Ayoola T. Brimmo, along with other researchers, used a 3D printer to create a functional, integrated, and inexpensive microfluidic probe (MFP) to study cancer cells and other living organisms in a Petri dish. Their research, recently published in journal Scientific Reports – Nature, suggests that 3D printers can provide a sophisticated, less expensive MFP, which works just as effectively.

Typically made of glass or silicon, MFPs are very tiny scientific tools — roughly the size of a pen tip — and were invented about a decade ago and are continuously being developed and refined. They are used by scientists around the world to study, process, and manipulate live cell cultures in a controlled environment.

While the technology is well established, it still poses unique challenges and limitations. MFPs cannot be easily produced on demand due to their complex fabrication procedures, and are expensive to make in large quantities because of their assembly procedures.

“3D printers provide a simple, rapid, and low-cost technique for fabricating MFPs,” said Qasaimeh, whose team developed a framework to print MFPs and quadrupoles in 3D.

“It’s cheaper to produce, easy to scale up, and fast to fabricate — all steps, from design to product, can be made in less than a day,” he explained, and as a result, “any science lab with a moderate resolution stereolithography printer will be able to fabricate 3D MFPs on demand and use them to process cells reliably.”

3D printed MFPs, “can deliver reagents in a localized manner, only a few tens of cells can be targeted within the culture dish, while leaving other millions of cultured cells untouched,” added Brimmo.

In an earlier study, Qasaimeh and his research team used a silicon MFP to discover how neutrophils respond to moving sources of concentration gradients that mimic infections and pathogens. The research analyzed how quickly these cells respond to stimulation, showed how neutrophils start their migrations at a maximal speed that slows over time, and how neutrophils undergo rolling-like behaviors before they start to pursue an infection site.

Qasaimeh is the principal investigator of the Advanced Microfluidics and Microdevices Laboratory at NYU Abu Dhabi, whose work focuses primarily on developing micro-tools for biologists working in human health research, including devices to capture circulating tumor cells taken from blood samples of cancer patients.

-Ends-

About NYU Abu Dhabi

NYU Abu Dhabi is the first comprehensive liberal arts and science campus in the Middle East to be operated abroad by a major American research university. NYU Abu Dhabi has integrated a highly-selective liberal arts, engineering and science curriculum with a world center for advanced research and scholarship enabling its students to succeed in an increasingly interdependent world and advance cooperation and progress on humanity’s shared challenges. NYU Abu Dhabi’s high-achieving students have come from 115 nations and speak over 115 languages. Together, NYU's campuses in New York, Abu Dhabi, and Shanghai form the backbone of a unique global university, giving faculty and students opportunities to experience varied learning environments and immersion in other cultures at one or more of the numerous study-abroad sites NYU maintains on six continents.

Disclaimer: The contents of this press release was provided from an external third party provider. This website is not responsible for, and does not control, such external content. This content is provided on an “as is” and “as available” basis and has not been edited in any way. Neither this website nor our affiliates guarantee the accuracy of or endorse the views or opinions expressed in this press release.

The press release is provided for informational purposes only. The content does not provide tax, legal or investment advice or opinion regarding the suitability, value or profitability of any particular security, portfolio or investment strategy. Neither this website nor our affiliates shall be liable for any errors or inaccuracies in the content, or for any actions taken by you in reliance thereon. You expressly agree that your use of the information within this article is at your sole risk.

To the fullest extent permitted by applicable law, this website, its parent company, its subsidiaries, its affiliates and the respective shareholders, directors, officers, employees, agents, advertisers, content providers and licensors will not be liable (jointly or severally) to you for any direct, indirect, consequential, special, incidental, punitive or exemplary damages, including without limitation, lost profits, lost savings and lost revenues, whether in negligence, tort, contract or any other theory of liability, even if the parties have been advised of the possibility or could have foreseen any such damages.