UNITED ARAB EMIRATES, DUBAI, December 23rd, 2012: Recent projects with leading global hotel chains and vegetable oil refineries have proven again that FEROX COMBUSTION SOLUTIONS make a serious difference on fuel oil fired boilers.

FEROX LLC is a company operating successfully since 25 years with only one single product line: "burn rate modifiers", products that enhance the quality of the combustion of petroleum distillate-based fuels, optimizing the energy release and reducing normal ware-and-tear of the equipment, being it corrosion, solid deposits on moving parts or on heat exchangers. FEROX is suitable for as well internal combustion engines, gas turbines as well as open flame applications such as boilers, asphalt factories and cement plants. The result of the burning rate modification is that internal pollution is reduced, heat exchange coefficients improves, scheduled maintenance stops are minimized, costly replacement of corroded heat-exchangers less likely or at least much delayed and the emission of environmental harmful substances will reduce drastically. Most of our clients find FEROX very cost-effective since the net fuel savings exceed the cost-price of the product, adding all the additional savings as bonus to the reduction of the Total Cost of Ownership of their equipment.

The Unites States Environmental Protection Agency has registered and certified FEROX as environmental safe and harmless product. FEROX does not contain any banned substances and is free to Import and Sale in the UAE, which we believe is also valid for any other GCC-country. FEROX is the result of 25 years of continuous use and on-going technical development. FEROX Bunker HF is Non-Dangerous as per IATA regulations.

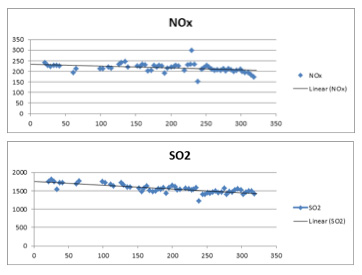

FEROX Bunker HF, the specialty product for heavy fuel oil, is renowned for its curative and preventive effect soot formation in HFO boilers. It has also a unrivalled protective effect against elevated levels of SOx and VOx, whereas at the same time the NOx emission are strongly reduced. This is show in the two below graphics of a 320 hours demonstration of the FEROX-effect.

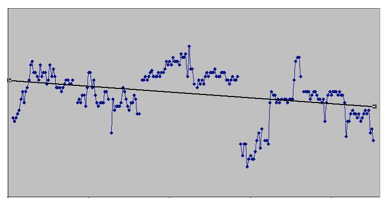

Below is the chart which shows the gradual reduction of the Stack Temperature in a recent start-up of using FEROX in one 45MT/day consuming HFO-fired boiler in Dubai, covering 3 weeks of operations. The peak in the last week was when one of the operators mistakenly feed the boiler from a second tank with non-treated HFO, with immediate negative effect on the burn rate efficiency.

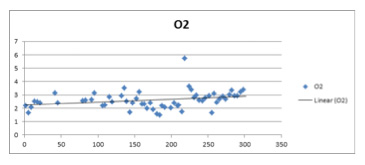

One other very clear effect of FEROX is that it optimises the O2 consumption of the combustion. This installation was not equipped with an automatic oxygen trim system and the below printed graphic clearly shows a gradual increase in free available O2 in the exhaust of nearly 40%. See again the immediate response of the measured value free oxygen around the 250 (hour) mark, when the supply of treated HFO was interrupted during 12 hours.

In line with the original application where Dr Parish, the inventor of the technology, has created FEROX for, increasing the payload of the space program by boosting the trust of the solid fuel rocket engines, is it a proven fact that HFO fired power plants that mix FEROX in the fuel, report an increased maximum power generation at significantly reduced costs. Ultimately does this also mean that in peek-demands, each plant will allow more power generation without the need for expensive and time consuming hardware extensions.

Mr. Jan Willem Van Es, Managing Director of Saham Star General Trading LLC (Distributor of Ferox in the GCC and Manufacturer's Marketing & Sales Partner for the EMEA) stated: "FEROX is a great product that helps in reducing carbon foot prints resulting to a cleaner environment". He continues: "We do understand the major impact the introduction of additives will have on our clients operations, but we do believe that the cost-benefit balance will be in favor of our product, which is believed by many to be the most cost-effective technology currently on the market."

He concludes: "FEROX COMBUSTION SOLUTIONS seriously reduces the Total Cost of Ownership of power plant and refinery operators, which is a given fact."

For more information about FEROX Fuel Tabs, please contact:

Jan Willem Van Es I Managing Director

Mobile: +971 50 5597459

Email: info@saham-international.com

Website: www.saham-internation.com

http://www.facebook.com/feroxcombustionsolutions.

© Press Release 2012