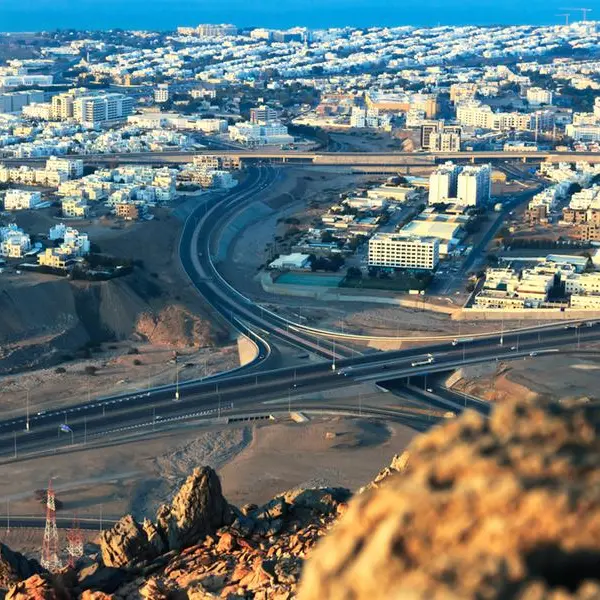

PHOTO

MUSCAT: With the Sultanate of Oman just months away from commissioning its $1.6 billion polysilicon production facility in SOHAR Port and Freezone, Oman is set to rank second only to China as one of the world’s largest producers of this strategic commodity — central to the global solar photovoltaic (PV) manufacturing industry.

United Solar Polysilicon, slated for launch before the end of this year, will be the first polysilicon project in the Middle East.

Once fully operational, the plant — designed with an annual production capacity of 100,000 tonnes — will position Oman as the second-largest producer globally, with an estimated 4.4 per cent share of worldwide capacity.

“The project aims to position Oman as a key player in the global photovoltaic (PV) manufacturing supply chain, reducing dependency on China-based production,” said the Oman Investment Authority (OIA), which has invested $156 million in the venture through Future Fund Oman (FFO), a platform that supports investments in strategic sectors of the Omani economy.

China remains a polysilicon manufacturing powerhouse, accounting for around 93 per cent (equivalent to 2 million tonnes per year) of the world’s total production capacity of 2.1 million tonnes. A distant second is Germany, with a 2.9-per cent share (65,000 tonnes), followed by the United States and Malaysia, each with 1.5 per cent (34,000 tonnes). In value terms, the global market was estimated at $34.3 billion as of end-2023.

According to OIA, the decision to site the polysilicon project in Oman was based on several competitive advantages, foremost among them government support.

“A national negotiation team streamlined discussions, ensuring a smooth process for securing leases, utilities and incentives,” noted Oxford Business Group in an Impact Report on Future Fund Oman.

Other factors influencing the investment decision included: Competitive electricity prices, crucial for maintaining profit margins; Proximity to SOHAR Port and Freezone, enabling efficient import of raw materials and export of finished products; Access to the US market via the Oman–US Free Trade Agreement (FTA), allowing tariff-free exports; and a favourable regulatory environment.

In addition, the project grants Oman a strategic entry into the global solar renewables supply chain. Detailing the production process, the Impact Report explained: “The solar PV manufacturing process begins with the production of high-purity polysilicon, which is then melted and shaped into cylindrical ingots.

“These ingots are sliced into thin wafers, forming the base for solar cells. The cells undergo various treatments to enhance their efficiency in converting sunlight into electricity.

“Finally, the cells are assembled into modules (solar panels) ready for installation in energy systems. This process is critical to the growth of renewable energy infrastructure worldwide.”

Currently, around 4,000 contractual construction workers are engaged in building the sprawling complex, which spans 160,000 m² within the SOHAR Port and Freezone.

During the operational phase, the plant will employ 1,000 to 2,000 staff, with Omanisation targeted at 70 per cent by 2030 through a combination of training and technology transfer programmes.

2022 © All right reserved for Oman Establishment for Press, Publication and Advertising (OEPPA) Provided by SyndiGate Media Inc. (Syndigate.info).