Samtech Qatar and Curb Appeal USA to demonstrate revolutionary new curbing machine on Thursday

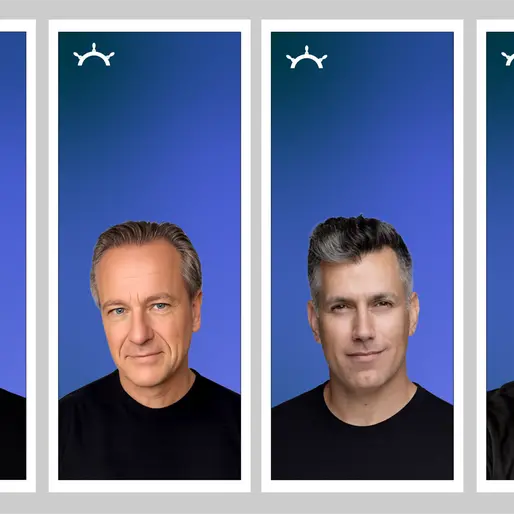

Doha, Qatar - As Project Qatar 2008 opened to thousands of visitors yesterday, a select few exhibitors displayed the potential to completely transform the landscape of the region's Building & Construction industry. First among them were Samtech Qatar and its partner, Curb Appeal USA. With their innovatively designed curbing machines, the two companies intend to do away with the cumbersome, expensive and labor intensive process of laying thousands of kilometers of curb, replacing it with their patented machines that are capable of laying over 1.5 km of curbing in a day, requiring only one man to operate, and eliminating wastage of material almost completely by laying as they go. "There's absolutely nothing else quite like these machines anywhere else in the world," promises Steve Caldwell, the president of Curb Appeal, who is in Doha for Project Qatar along with his partner and designer of the cutting edge machines, Ed Taylor. "The kind of efficiency these machines offer for their price and operating costs is unmatched," he added. The curbing machine is scheduled for a live demo on Thursday, April 10th, at 5 pm at the companies' stand at Project Qatar(Booth A43).

Curb Appeal has been designing, developing and manufacturing curbing machines specifically for the landscaping industry for the last seven years, giving shape to lawns, parks and some of the finest luxury resorts and hotels. Ed Taylor has spent the last 38 years designing and perfecting commercial curbing machines around the world. "Our alliance brings us together as the only manufacturer of concrete curbing machines in the world whose operations span the whole gamut from landscape to curb & gutters, which is the largest curb that can be poured," says Caldwell. Curb Appeal's machines are capable of reproducing hundreds of styles and shapes of curb, including all types of pre cast designs that are currently in use in Qatar. The machines have found wide acceptance in the USA and elsewhere, and are currently in active use in all 50 US states as well as in 30 other countries around the globe.

The biggest of the three machines, the PC 600, is capable of pouring up to 48 inches wide at a speed of 30 feet every minute. "This is the same capability you'll find in the bigger machines on the market that take large crews to run and cost hundreds of thousands of dollars," points out Caldwell. "The PC 600 delivers the same performance at fraction of the cost and takes just one man to run." Capable of laying over 1.5 km of curbing in a single day, an increase in production of over 1000% over conventional methods is not out of the question.

In much of the region, curbing is currently pre-cast in factories and laid by an army of laborers who painstakingly place the pieces one at a time. Not only is this method slow and labor-intensive, it also results in considerable wastage of concrete in the form of rejected blocks as well as during the manufacturing process. With the curbing machines from Curb Appeal, wastage is almost completely eliminated. "You can actually calculate your concrete requirements and end up within a few feet of your target distance at the end of the day," says Taylor, the designer of the machine. "Besides, the technology we use in the machine compacts the concrete by vibrating it at very high RPMs to make it much stronger than pre-cast blocks." The machine is also capable of pouring over rebars for added strength if required.

Already on his third trip to Doha in the last nine months, Caldwell has partnered with Qatar based Samtech to bring Curb Appeal to Qatar. Under the leadership of General Manager Ammar Ammar, Samtech has already built a solid foundation from which to launch the Curb Appeal machines with full technical and sales support in Qatar, and even secured a warehouse for inventory. "We are ready, willing and able to provide turnkey solutions for all your curbing needs."

Samtech will serve as the regional partner, distributor and service agent for Curb Appeal products for the entire GCC region, with Qatar being the hub thanks to its central location and favorable business environment.

All curbing units also have the added advantage of being GPS enabled. "All you need to do is plug in the coordinates of the job site into the 3D GPS system, and the unit can be tracked and driven remotely via the GPS system," explains Caldwell. In addition, the Curb Appeal units are the only machines of their kind to have an independently floating hopper that adjusts its elevation as the machine moves over uneven terrain, resulting in the laid curb being perfectly even. A trademarked hoist system is also available that allows the machines to be loaded or unloaded from any kind of truck in less than two minutes.

Another nifty innovation is the Curb Appeal X-Factor concrete additive, which has been engineered to be completely environmentally friendly. The additive eliminates shrinkage and triples the strength of the concrete, as well as being a sealer and possessing waterproofing properties. It also drastically reduces efflorescence.

With so many features engineered into the wieldy machines, they mark a considerable upgrade to anything that's available on the market. And with the tremendous boom in Qatar's construction industry, the Curb Appeal machines will undoubtedly find many eager takers in the country. "It's just a matter of time before we're all set to begin operations in Qatar," says Caldwell. "Meanwhile, we're confident that our exhibit and demonstration at project Qatar gives the Qatari construction industry an idea of the exciting opportunity that exists in this market."

-Ends-

© Press Release 2008