Gulf Extrusions, the UAE-based pioneer and market leader in aluminium extrusion in the GCC region, has developed a new aluminium alloy that can sustain high quality surface finish at significantly high extrusions speeds. The new alloy can be used as raw material through extrusion processes accelerated to an amazing 133 per cent higher than normal production speeds. While optimizing machine use for extruders, the alloy will ensure higher productivity without requiring higher investment in production equipment.

"For an extruder, it is always a challenging goal to improve machine output and achieve higher metal recovery. The development of the new alloy was a result of Gulf Extrusions investment into improved product quality, as well as optimised extrusion processes," explained Robert Holtkamp, Director of Sales and Marketing, Gulf Extrusions. "That means, with the existing infrastructure Gulf Extrusions will now have significantly higher production capacities, without compromising in any way on the structural strength or surface quality of the extruded profiles."

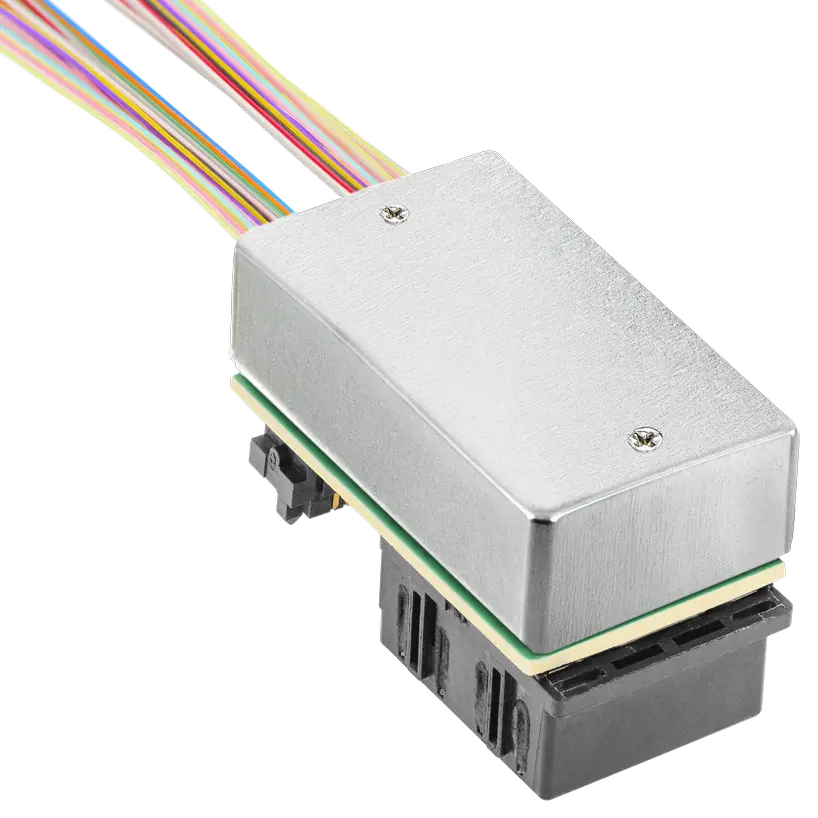

The development of the alloy was the result of an experiment that was carried out by Gulf Extrusions, with the support of Dubai Aluminium Company Limited (Dubal), over a period of two years. The objective of the experiment was to examine and improve upon the output limitations of normal extrusion processes. It was noted that many factors influence machine output; with one of the most important being the speed at which the extrusion process takes place. The existing composition of the aluminium alloy 6063 (most commonly used in extrusion processes) could support speeds of approximately 30 m/min (metres per min). At speeds higher than this, the extruded profile becomes prone to problems such as high temperature surface cracking (or hot tearing), resulting in poor surface finish and lower over all quality.

During the experiment, Gulf Extrusions trialled 4 different aluminium alloy compositions, as well as improved die designs to facilitate higher m/min ratio, without affecting the surface finish. While die correction was carried out by rounding off edges to improve surface finish, the four alloys went through process tests as billets (raw material for extrusion); through the extrusion process; and through the anodizing process for achieving the final profile finish.

The chosen alloy could sustain improved extrusion speeds ranging from 87.5 per cent to 133 per cent, depending on the extrusion die used. Besides sustaining high speeds and delivering extremely good results for all kinds of surface treatments, including anodizing, the new alloy also facilitates extrusion of complicated profile shapes without creating any process difficulties. It has also been extensively tested for quality and strength and has proven to have mechanical properties of the highest standards.

"Gulf Extrusions commitment to quality and innovation goes back more than a quarter of a century, to the time of the company's inception. Over the years, Gulf Extrusions has become the market leader for aluminium extrusion profiles in the GCC region. The company has also captured significant market share of the aluminium extrusion imports made by the UK, Germany and Canada, as well as many other countries around the world. This new development will ensure that the Gulf Extrusion brand becomes synonymous around with the world with best of breed aluminium profiles," said Holtkamp.

-Ends-

About Gulf Extrusions

Gulf Extrusions is the largest extrusion plants in the Gulf with a 27 year history of top quality production. Located at Jebel Ali, it is minutes away from one of the busiest sea ports in the Gulf. The plant is designed to produce aluminium sections in mill finish, silver, bronze, gold and colour anodized, and powder coated finishes. The modern processing equipment and techniques permit the company to produce a range of over 7,000 profiles. These vary from architectural sections to components for household items, AC grills and customized products. Nearly 60% of the output generated by Gulf Extrusions is used in the local market to support the building and construction projects. Gulf Extrusions also exports to various markets in GCC and Middle East countries, as well as markets in Europe, West Africa, Asia and Canada.

For further information, please contact:

Orient Planet

PR & Marketing Communications

PO Box 23345,

Dubai,

UAE

Tel: +971 4 3988901

Fax: +971 4 3988941

Email: info@orientplanet.com

Website: www.orientplanet.com

© Press Release 2004