The company is investing in long-term testing and development. Its latest piloting of DOW™ Ultrafiltration Modules provided continuous, quality feedwater to Reverse Osmosis system downstream for almost a year, while also demonstrating a reduction in overall costs.

Dubai, UAE - August 11, 2015: Dow Water & Process Solutions, a business unit of The Dow Chemical Company (NYSE: DOW) and global leader in sustainable water separation and purification technologies, is demonstrating its dedication to research and development (R&D) through investment in progressive product piloting. As part of this continued research, the company has announced the results of a recent piloting focused on DOW™ Ultrafiltration technologies, which was carried out at its Global Water Technology Center in Tarragona, Spain, and saw continuous, excellent quality feedwater supply to the Reverse Osmosis system downstream over a prolonged period.

The pilot program aimed to monitor the quality of the feedwater produced by the DOW Ultrafiltration system, in order to be able to provide support for Dow Water & Process Solutions' wide range of Ultrafiltration technologies, as well as reinforce its ongoing dedication to R&D and improvement of its products and solutions. The data generated is used both to prove the success of its existing solutions and to validate and qualify new products before their launch into the market. The results of the piloting confirm sustainable and stable operation of DOW Ultrafiltration commercial modules as a pre-treatment for the Reverse Osmosis system downstream for more than 300 accumulated days, demonstrating their excellence and robustness in a real wastewater reuse application with relatively high organic content.

Verónica García, EMEA technical service and development manager, Dow Water & Process Solutions, explains, "This type of pilot experiment does not usually last more than few weeks, and therefore the long duration of the DOW Ultrafiltration piloting emphasizes the company's long-term commitment to product development and continued research."

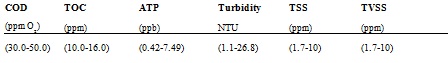

Table 1. Feed water quality parameters of the municipal Waste Water Plant

In order to provide real wastewater conditions, the pilot system was fed with secondary effluent from the Vilaseca (Tarragona-Spain) municipal wastewater treatment plant. Typically, due to wastewater feed quality and characteristics, the Reverse Osmosis system cannot be fed directly from the secondary effluent of the wastewater treatment plant without interruption. Therefore, to guarantee the required feed quality to the Reverse Osmosis system, a DOW Ultrafiltration SFP-2880 system was integrated upstream.

The autopsies carried out on the Ultrafiltration modules following the end of the piloting demonstrated the absence of broken or damaged fibers, as well as no reported loss in tensile strength and mechanical properties. Based on these test results, it can be concluded that DOW Ultrafiltration elements are an excellent pre-treatment for Reverse Osmosis systems. The permeate produced by the system downstream is suitable for a number of applications, such as for irrigation purposes, either for golf courses or for agriculture. Precisely, the agricultural sector represents 80% of water use in the country, so integrating advanced technologies such as DOW Ultrafiltration elements into the sector could help increase efficiency.

Economic solutions to achieve the highest standards

Another important finding from the study is the associated cost reduction resulting from the combination of DOW Ultrafiltration and DOW FILMTEC™ Reverse Osmosis technologies. For instance, DOW Ultrafiltration systems require a lower footprint when compared to other methods of conventional pre-treatment technologies, such as sand filtration. In addition, less chemical cleanings are required in the DOW FILMTEC Reverse Osmosis system downstream due to the more suitable feed water provided by the DOW Ultrafiltration system, resulting in longer membrane life, higher plant availability and lower replacement rate of cartridge filters.

Zakia Bahjou, ME, Africa & Turkey Regional Commercial Manager, Dow Water & Process Solutions, says, "We are committed to investing in research and development to ensure the highest quality and efficiency of our products, not only in Spain and Europe, but also in the Middle East and across the globe."

DOW Ultrafiltration modules stand out for their hydrophilic PVDF hollow fibers, which feature high strength, chemical resistance and low-fouling tendency, as well as their optimized flow configuration (OUT-IN) for high tolerance to a wide variety of feed water types, minimizing the risk of fiber plugging.

Dow Water & Process Solutions' Global Water Technology Center in Tarragona

With the focus of advancing human progress and sustainable living, Dow Water & Process Solutions' Global Water Technology Center in Tarragona offers a powerful combination of high-tech R&D lab and plant that has become the largest clean water research and development facility in the world. The plant, which covers more than 3,000 square meters, processes 10,000 daily cubic meters of water, enough to provide for a town of 100,000 people.

The combination of on-site simulation and laboratories enable high-class testing and optimization of water treatment and reuse applications, as exemplified with the DOW Ultrafiltration pilot unit. Research related to areas such as improving quality of desalinated water, minimizing costs and energy consumption, extending the useful life of membranes and increasing the materials' efficiency is deployed in various pilot units able to asses up to 40 products at real-world scale in order to test all new technologies and applications before their launch to the market.

Dow Water & Process Solutions in the Middle East

Dow Water & Process Solutions established its first manufacturing and commercial facilities in the United Arab Emirates more than 40 years ago. Already with a solid presence in the Middle East petrochemicals industry, Dow Water & Process Solutions is partnering with leading regional companies to set up state-of-the-art water and process solutions plants across the Middle East. Dow Water & Process Solutions is regionally headquartered in Dubai, United Arab Emirates and has a commercial and manufacturing presence throughout the Middle East, North Africa and Turkey (MENAT).

Key projects include a Reverse osmosis manufacturing facility in the Kingdom of Saudi Arabia, and a collaboration with King Abdullah University of Science and Technology (KAUST), which has served as a water technology research center and a region hub for research and development since early 2014.

™ Trademark of The Dow Chemical Company ("Dow") or an affiliated company of Dow.

About Dow Water & Process Solutions

A global leader in sustainable separation and purification technology, Dow Water & Process Solutions, a global business unit of The Dow Chemical Company, is making a clear impact in the world. We're helping to make water safer and more accessible, food taste better, pharmaceuticals more effective and industries more efficient and spearheading the development of sustainable technologies that integrate water and energy requirements. Dow Water & Process Solutions offers a broad portfolio of ion exchange resins, reverse osmosis membranes, ultrafiltration membranes, fine particle filters and electrodeionization products, with strong positions in a number of major application areas, including industrial and municipal water, industrial processes, pharmaceuticals, power, residential water and waste and water reuse. Follow Dow Water & Process Solutions on Twitter and LinkedIn, and visit our website for more information www.dowwaterandprocess.com.

About Dow

Dow (NYSE: DOW) combines the power of science and technology to passionately innovate what is essential to human progress. The Company is driving innovations that extract value from the intersection of chemical, physical and biological sciences to help address many of the world's most challenging problems such as the need for clean water, clean energy generation and conservation, and increasing agricultural productivity. Dow's integrated, market-driven, industry-leading portfolio of specialty chemical, advanced materials, agrosciences and plastics businesses delivers a broad range of technology-based products and solutions to customers in approximately 180 countries and in high-growth sectors such as packaging, electronics, water, coatings and agriculture. In 2014, Dow had annual sales of more than $58 billion and employed approximately 53,000 people worldwide. The Company's more than 6,000 product families are manufactured at 201 sites in 35 countries across the globe. References to "Dow" or the "Company" mean The Dow Chemical Company and its consolidated subsidiaries unless otherwise expressly noted. More information about Dow can be found at www.dow.com.

For further information contact:

F. Félix Albarrán

Dow Water & Process Solutions

+41 44 728 21 11

falbarran@dow.com

Leah Tucker

Edelman

+971 50 613 9356

Leah.tucker@edelman.com

© Press Release 2015