Imagine a solid wood that is sourced from fast-growing sustainable forests, has zero toxicity and provides dimensional stability and durability that exceeds even the best tropical hardwoods. Such a wood exists

It's a wood that can replace increasingly scarce tropical hardwoods, treated woods and less sustainable materials in new and existing outdoor applications. A wood that will act as a better carbon sink during its extended life span and can be safely recycled at the end.

Accoya - the world's leading high technology wood - is the perfect answer for builders looking for a sustainable, environmentally-friendly product, which matches or exceeds the durability and stability of the very best tropical hardwoods.

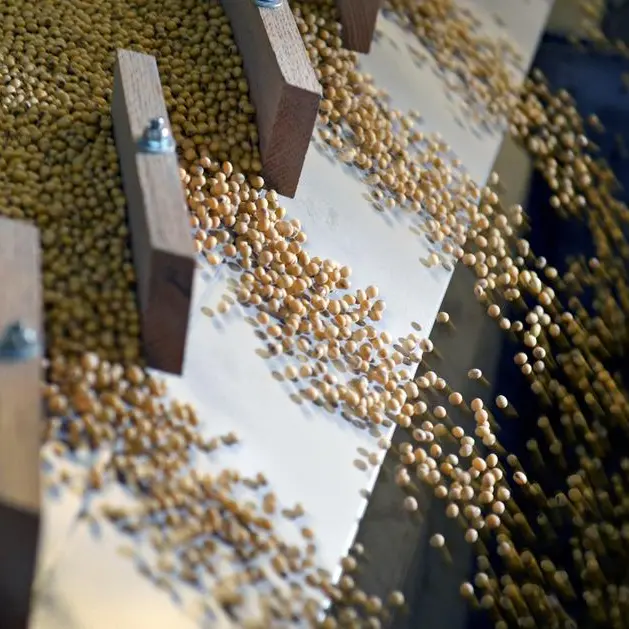

This high performance wood - brainchild of Accsys Technologies - is created from sustainably-sourced softwood which undergoes a proprietary, non-toxic acetylation process that permanently modifies the wood to the core. The result is an environmentally-friendly solid wood with excellent durability, dimensional stability and beauty. The acetylation process was studied for over 80 years before Accsys Technologies built its production facility in 2007, and then introduced Accoya to the North American market in 2008.

The Accoya production process takes sustainably-sourced, fast growing softwood and, in a non-toxic process that 'enables nature', creates a new durable, stable and beautiful product - that has the very best environmental credentials.

It is perfect for demanding applications such as windows and doors, where it is important that tolerances are tight yet regardless of the conditions, they open year round. Accoya is perfect for siding where wood's natural beauty is desired, but sustainability and high performance are of the utmost importance. In decking, where it is important that boards do not warp, twist, bow or split, Accoya is up to the challenge as well.

The exceptional properties of durability, stability, strength and beauty have even led to Accoya being used as the main construction material in a heavy traffic road bridge with a highly original design.

Sustainability

Accoya is helping to protect the world's precious hardwood resources and is guaranteed for 50 years in exterior use and 25 years when used in the ground. This long life also provides an added benefit - helping to reduce carbon emissions.

The wood is sourced from sustainable sources, including FSC and has class leading environmental credentials such as Cradle to Cradle Gold certification by the highly prestigious McDonough Braungart Design Chemistry (MBDC) organization.

Accoya acetylated wood creates beautiful and sustainable possibilities, even in demanding applications. Most commercially available glues can be used with Accoya, and it can be machined in the same way as unmodified wood and machines more like a harder wood. It does not require any specialized equipment and is no harder on tools than wood such as oak.

It can also be coated like an unmodified wood. Because Accoya is so dimensionally stable and durable, the coatings last significantly longer even in the harshest of conditions, maintenance of the coating system can be increased up to 10-15 years (3-5 years is the average for unmodified wood under normal circumstances).

Accoya typically costs in the range of an African mahogany. The performance characteristics of Accoya compete with the best, old-growth tropical hardwoods, which are far more costly than Accoya. It is also suitable for a wide range of applications, including window frames, doors/shutters, cladding/siding, decking, garden furniture, bridges, and boat building.

Outstanding Performance

Extensive laboratory and field testing by leading institutes around the world (including in New Zealand, USA, UK, Sweden, Malaysia, Indonesia, Russia, the Netherlands and Japan) has shown the performance of acetylated wood to be extremely reliable.

Accoya has been thoroughly tested for dimensional stability, durability, UV resistance, paint retention and in-ground conditions to ensure optimal performance. For many years it has been - and continues to be - used by scientists as the benchmark against which other treatments and modifications are measured.

Guaranteed for 50 years in above ground exterior use and 25 years for in the ground use, Accoya also helps to protect the world's precious hardwood resources. Currently, Accoya is commercially available only with the radiata pine base. Accsys Technologies has successfully acetylated many different types of wood in an R&D environment and plans to commercially introduce Accoya with other bases in the near future.

[Box]

THE ACETYLATION PROCESS

Acetylation effectively changes the free hydroxyls within the wood into acetyl groups. This is done by treating the wood with acetic anhydride, which comes from acetic acid (known as vinegar when in its dilute form). When the free hydroxyl group is transformed to an acetyl group, the ability of the wood to absorb water is greatly reduced, rendering the wood more dimensionally stable and, because it is no longer digestible, extremely durable.

The acetylation process permanently modifies the wood from the surface to the core. For example, if a 4" x 4" x 4' piece of Accoya were machined into toothpicks, every toothpick would have the exact same performance characteristics. Acetylation causes no significant change in the strength of wood. Hardness, however, is increased by up to 10 percent, unlike thermal modification by which strength is typically reduced by 15-25 percent.

The process is relatively environmentally-friendly as well. The chief byproduct of the process is acetic acid, which is non-toxic and biodegradable, and can be recycled into the compound used for the acetylation, acetic anhydride, or sold into the substantial acetic acid market. Besides a small amount of natural resins isolated from the wood, the acetylation process produces very little waste.

[Box]

ACCOYA APPLIED

In Sneek, The Netherlands, multiple heavy-traffic bridges have been made entirely of Accoya glued laminated timber (glu-lam) beams and have been certified for an 80-year life.

When converting a Quonset hut and warehouse into an office complex near the large West 7th development project in Fort Worth, Texas, applications of Accoya included lap siding, rain screens, and an additional profile on the warehouse. Accoya was chosen for the rain screens to take advantage of its thermal insulation qualities, which limit heat absorption.

The University of Florida's Solar Decathlon house also uses Accoya for the five adjustable shading devices that surround the exterior. These screens also act as protection against rain and wind and provide privacy control. The screens can endure extreme weather conditions without compromising strength or durability.

KEY FEATURES

Naturally Beautiful

Accoya creates beautiful and sustainable possibilities, even in demanding applications. Not only is its durability proven, but it has also been shown to retain its appearance, requiring much less frequent maintenance than most other solutions. This gives added reassurance to manufacturers, architects, specifiers, builders and property owners alike and makes Accoya the ideal choice for a diverse range of external applications.

Non-Toxic

Accoya is non-toxic. The proprietary acetylation process used to produce Accoya adds nothing to the wood that is not already naturally present, protecting the environment from the harmful effects of poison in treatments leaking into the earth. This also means that Accoya may be safely reused and recycled.

Sustainably Sourced

All Accoya is produced from well-managed sustainable sources, including FSC, PEFC and other regionally certified woods.

Consistent Supply

All Accoya is produced from abundantly available and fast-growing sources such as radiata pine. Radiata pine yields 28 cubic meters per hectare per year. By comparison, bamboo yields 11 cubic meters per hectare per year, and teak yields 6 cubic meters.

100 percent Recyclable

Because Accoya contains no toxic chemicals, it is fully reusable and recyclable. Of course, reuse is always preferred but Accoya may be safely incinerated for bio-energy or composted.

Carbon Footprint

Accoya is an environmentally compatible substitute for carbon intensive building materials such as steel, concrete and aluminum. In many applications, its service life is much longer.

Dimensional Stability

Swelling and shrinkage is reduced by 75 percent or more in Accoya. Doors and windows open effortlessly year round. Paints and varnishes last 3 or 4 times longer, greatly reducing maintenance costs.

High Durability

The most durable wood possible, it is more durable than teak and other highly durable woods, making it perfect for outdoor use.

Long Lasting

Accoya lasts at least 50 years above ground and 25 years in ground.

Rot and Insect Barrier

Accoya is indigestible to insects and micro-organisms and is therefore more resistant to decay. Protected from wood-destroying fungi, Accoya is virtually rot-proof.

Perfect for Coating

Easier to coat: less preparation and sanding between coatings required. Accoya has improved dimensional stability and UV resistance. The process improves the life of coatings. It is perfect for transparent, translucent and opaque coatings.

Naturally Insulating

Accoya offers improved thermal insulation in comparison with commonly used wood species. It is ideal for applications where energy conservation is important.

UV Resistant

Accoya has superior resistance to UV degradation when translucent coated. Its natural appearance lasts longer. Accoya is the ultimate substrate and coating life is increased.

Retained Strength and Hardness

The process does not compromise the wood's strength, rather, the hardness is increased. High strength to weight ratio makes it suitable for challenging applications.

Consistent Quality

Consistent, measurable modification quality from surface to core. No need to apply chemical preservatives when cut or planed.

Machinability

Accoya is easy to machine and process manually, creating no challenges for product manufacturers and end users.

© Timber Design & Technology 2012